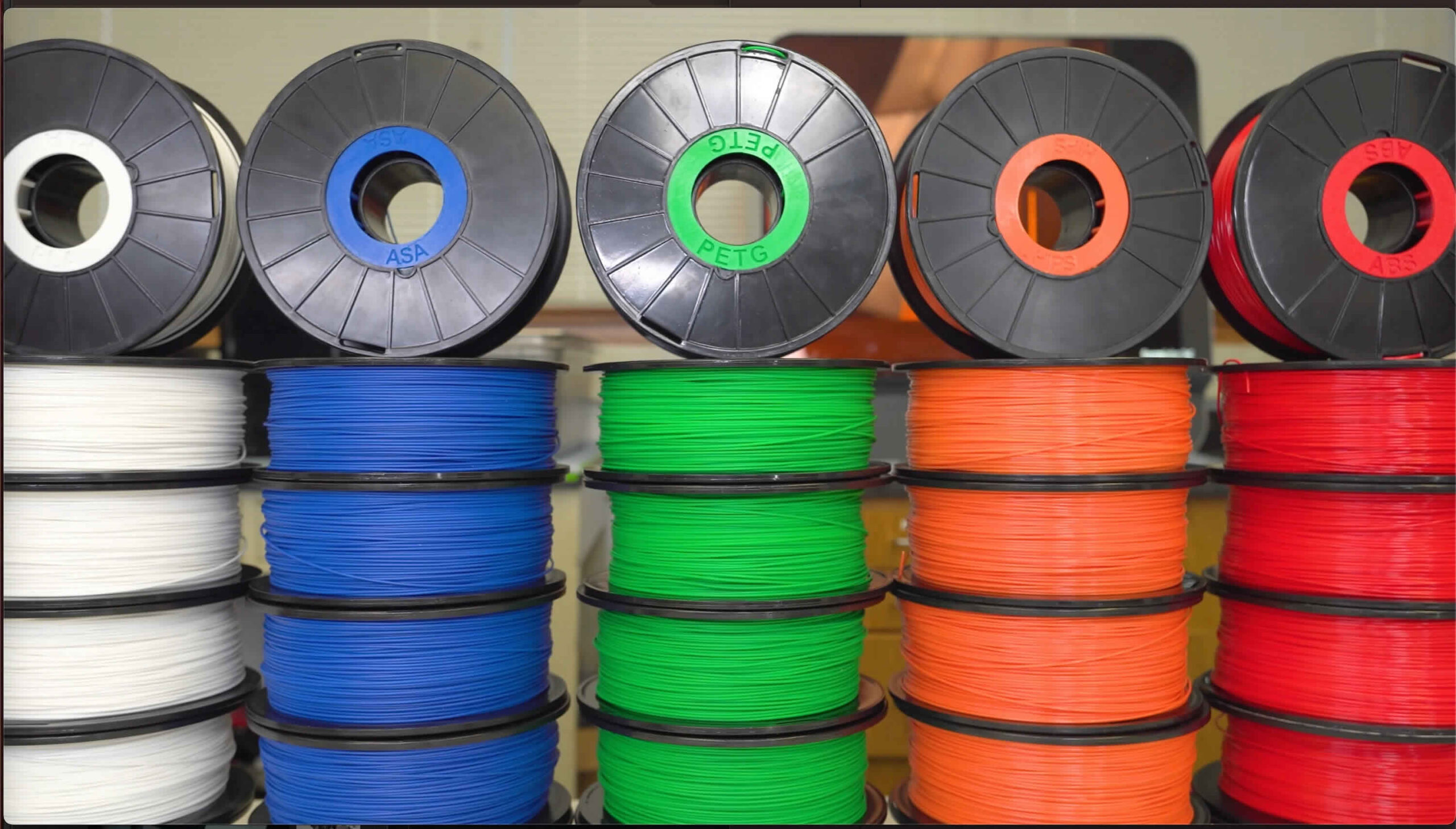

Choosing & buying 3D printing filament isn’t about guessing or just grabbing the spool with the coolest color. Each material has strengths, weaknesses, and ideal use cases. If you match the filament to the job, your prints look cleaner, last longer, and actually perform how you expect. Below, we break down the most popular materials and the smartest way to use them.

PLA – Everyday Projects, Clean Detail, Easy Wins

PLA is the people’s champion for a reason. It’s easy to print, looks great right off the bed, and doesn’t require you to tweak a million settings. Best uses include visual models, cosplay props, desk décor, miniatures, school projects, and prototypes where strength and heat resistance aren’t critical. Not ideal for: car parts, outdoor components, or anything that sits in a hot environment. It softens in heat, so car interiors or direct sun? Hard pass.

PETG – Strong, Practical, and Ready for Real Projects

Think of PETG as the helpful best friend who can handle practical tasks. It’s tougher than PLA, slightly flexible, and resists water and impact.

Great for brackets, functional organizers, enclosures, drone parts, outdoor prints, and anything where durability matters.

Heads-up: it can string if your retraction and temps aren’t dialed in, but when tuned, PETG is a workhorse.

ABS & ASA – Tough, Heat-Resistant, and Serious-Duty

ABS is the classic engineering plastic. It handles heat, stress, and post-processing like sanding or acetone smoothing. ASA takes this further with UV-resistance, making it the go-to for outdoor applications. Best uses: automotive clips, tool housings, protective components, and outdoor hardware. You’ll need good ventilation and preferably an enclosure because ABS loves to warp without heat control.

TPU – Flexible, Elastic, and Shock-Safe

If you need something that bends, cushions, or absorbs impact, TPU is your friend. Best uses: phone cases, protective bumpers, RC tires, gaskets, insoles, vibration-dampening parts. It prints slower and requires consistent extrusion, but the results are worth the patience.

Nylon – High-Strength Industrial Performance

Nylon is extremely strong, abrasion-resistant, and ideal for demanding mechanical parts. Best uses: gears, hinges, drone frames, robotics components, tool adapters. It needs dry storage and a dialed-in temp setup, but once mastered, it delivers professional-grade results.

Composite Filaments – Wood, Carbon Fiber, and Metal Effects

- These blends give you style or strength upgrades, depending on the filler.

- Wood PLA prints look organic and can be sanded or stained.

- Carbon fiber composites boost stiffness for brackets and lightweight components.

- Metal blends add weight and shine, perfect for art, jewelry, or display models.

- Just remember: abrasives like carbon fiber need a hardened nozzle.